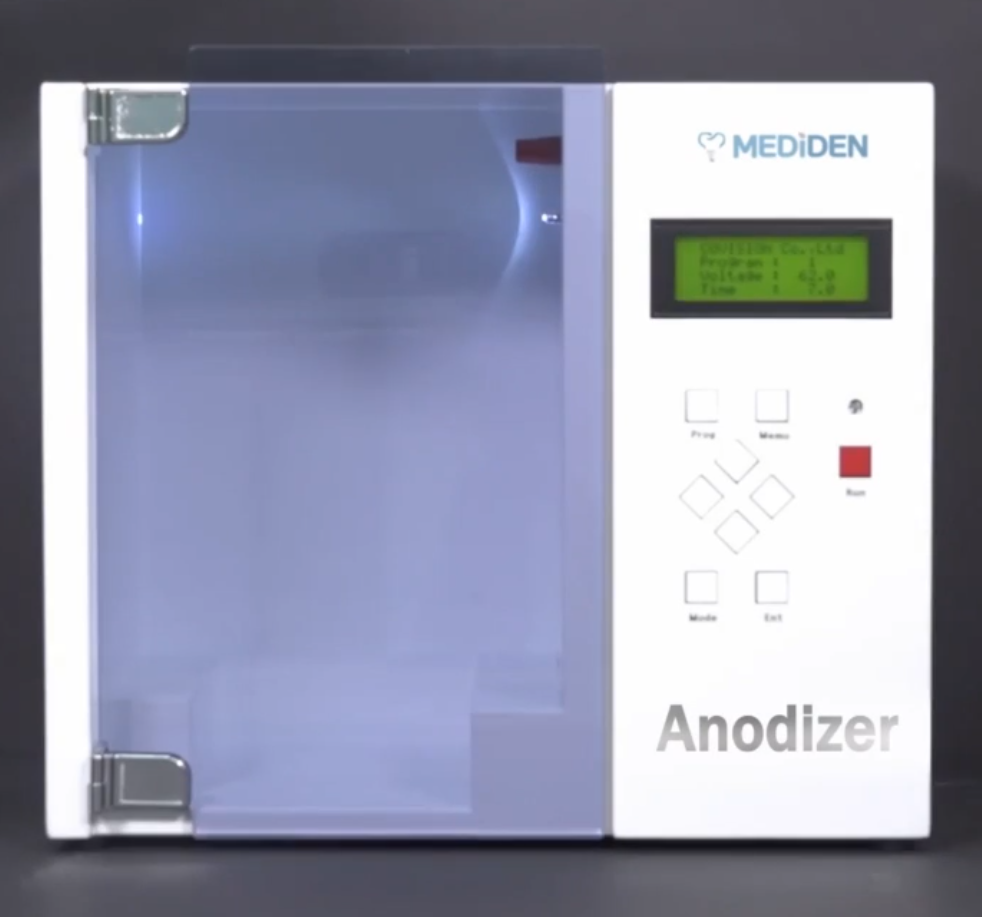

Titanium Abutment Anodizing Machine

Shipping calculated at checkout.

Titanium Abutment Anodizing Machine is backordered and will ship as soon as it is back in stock.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Anodizing is a process of treating the surface of an aluminum to convert it to aluminum oxide. Anodizing machines make this process more efficient, while providing the most reliable finish.

Advantage

- Good wear resistance

- Excellent corrosion resistance

- Clear Color

- No burning phenomenon

- High uniformity film

- Corrosion resistance is greatly improved

- Colorization is possible

- Less cracks

Specification

- Manual Variable - Voltage, Intensity and Time

- Data Save (up to 20) and Data Recall

- Ovp / Ocp Protection

- 7 Single Jig Hole

Colour Chart of Voltage

How To Use (Single Jig)

1. Add provided solution into tray,2. Put tray inside the machine with cover on.

3. Connect black cable to the center connector.

4. Connect other side of cable to the same color connector.

5. Choose a suitable jig for the abutment. Attach the abutment to the jig and fix it with a screw.

6. Remove the jig from the Mulit Jig Jack under the center of the tray cover and insert the red cable.

7. Place the jig in the desired hole. (Check if the abutment is submerged in solution. Add more if not.)

8. Shut the door. Press RUN if you want to run Program : 1 straight away.

9. If you want to change the program number, keep pressing PROGRAM until you see the number you desired, then press ENTER. Press RUN to start the work.

10. LED light turns on and the power turns off automatically after 10 seconds.

Titanium Abutment Anodizing Machine is backordered and will ship as soon as it is back in stock.