All-in-One DOF CRAFT 2 Milling Machine

Shipping calculated at checkout.

All-in-One DOF CRAFT 2 Milling Machine is backordered and will ship as soon as it is back in stock.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

DOF CRAFT 2 - All-in-One Milling Machine

The Evolution of a Steady Seller, the Beginning of an Upgrade

|

|

|

| Equipped with a servo motor | 35° Milling on the B-axis Without Angle Limitation | 15-inch Large Screen |

| Core Upgrades | CRAFT 5X | CRAFT 2 |

|---|---|---|

| Motor |

Step

|

Servo

|

| Display | 12-inch, 1280×720 | 15-inch, 1920×1080 |

| MOTIONAPP |

2.0

|

3.0

|

| B-axis machining angle | ~25° | ~35° |

| Dimensions(W×D×H) | 440 × 660 × 710mm | 545 × 670 × 710mm |

|

|

The CRAFT Series Overcomes Angular Limitations

With a C-type clamp, CRAFT 2 perform 90° milling by positioning the block vertically, allowing precise milling of the outer surfaces of teeth. Thanks to the open structure of the C-type clamp, when the block is placed at 90°, tools can access undercut areas unreachable at 0° or 180°, achieving more delicate details.

|

|

New Possibilities with 35° Milling, Opened by CRAFT.

The CRAFT series rotates the B-axis up to 35°, enabling precise results in deep undercuts and full-arch prosthetics without angle restrictions. A high-performance servo motor and rigid monoblock frame guarantee vibration-free accuracy at any angle, allowing even large prosthetics to be milled precisely from thinner zirconia blocks.

|

|

A Completely New Way of Producing Abutments

Traditional methods for custom abutments involve designing, milling, and rescanning in multiple steps. With one-step milling, both the custom abutment and the superstructure are manufactured simultaneously, drastically reducing the workflow. For example, while zirconia bridges are being sintered, abutments can be milled — saving over a full day of work. This also eliminates scanning errors, enhancing accuracy of the final result.

|

|

|

|

Smart Connectivity Anytime, Anywhere

Check everything from machine status to milling progress in real time, anytime and anywhere. Keep your workspace in your hand with the mobile-only Motion App, With the DOF Sync App for PC, you can manage schedules, processing history, and status notifications all in one place. Start faster and more efficiently with a seamless, smart workflow.

More than just an upgrade - All-new! Motion App

|

|

|

|

Tool life at a glance |

Customized control optimized for workflow |

Smart control system that anyone can operate easily |

|

The intuitive UI lets you grasp each tool’s life and position at a glance, |

From tool selection to milling sequence and starting point — everything can be freely set according to your needs. Interrupted tasks can be easily resumed, with real-time monitoring of progress and status. |

From axis movement to start-point setup, everything is visualized for intuitive |

Features

|

|

| AC Servo Motor | Wet & Dry Compatible Milling |

|

|

| 5-Axis Simultaneous Processing | Sturdy & Low-Vibration |

|

|

| Larger Screen, Smarter Control | High Quality Spindle |

|

|

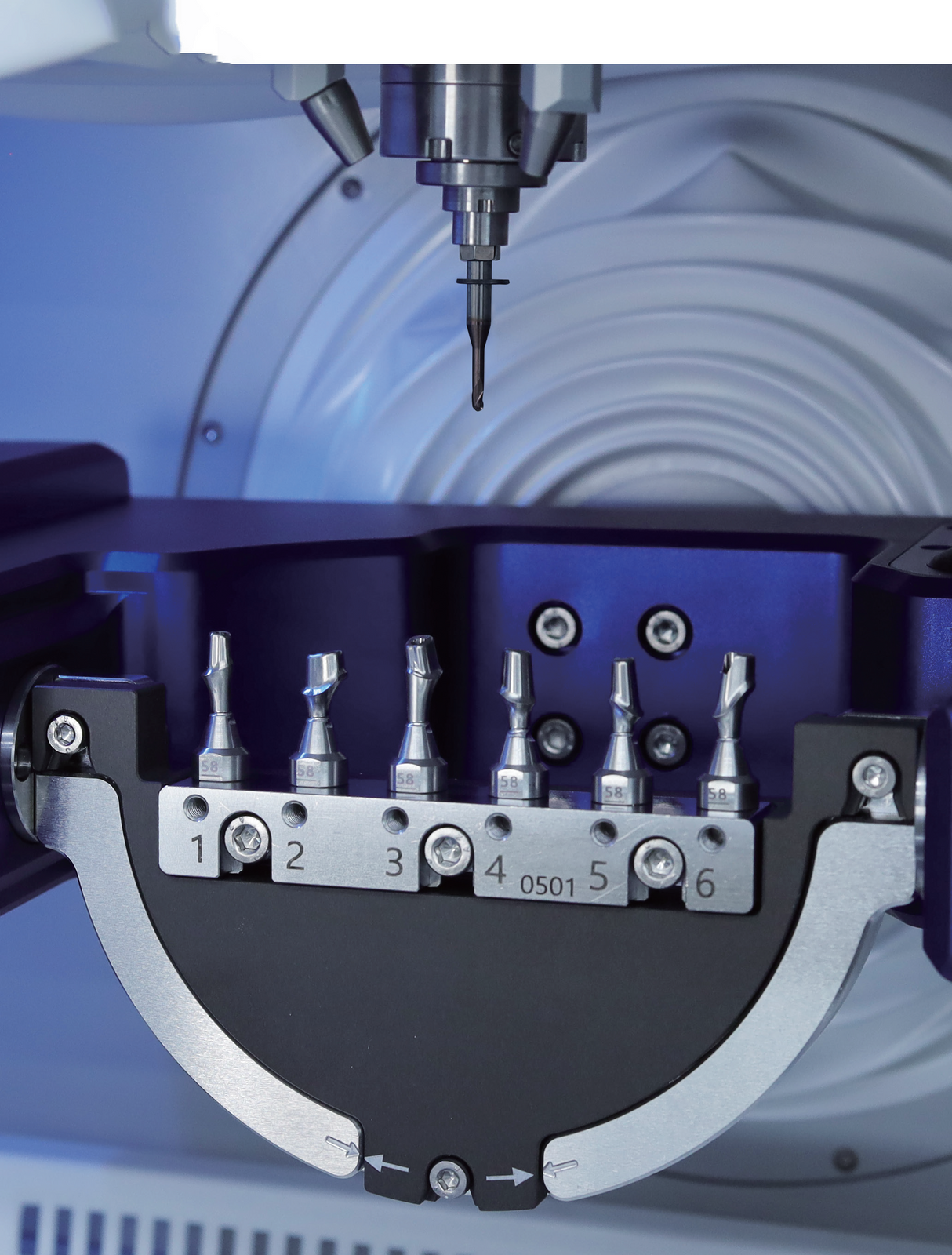

| 21 Station Automatic Tool Changer | Storage |

Materials & Indications

| Coping / Crown | Bridge | Inlay/Onlay | Veneer | Over Structure | Abutment | |

|---|---|---|---|---|---|---|

| G/C, H/C | ✓ | ✓ | ✓ | ✓ | ||

| Zir, PMMA, Wax | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Pre-milled | ✓ |

Optional Jig

|

|

|

|

| Premill Original Jig | Premill Reverse Jig | Glass Ceramic Jig | Hybrid Ceramic Jig |

|

|

|

|

| Hybrid Ceramic Jig (8T, 10T) |

C-Hexa Type Jig (8T, 10T) |

Non-Hex Jig | Inlay Holder |

Specification

| Product Name | CRAFT 2 | |

|---|---|---|

| Feature | Motor | AC Servo Motor |

| Spindle power | Max. 0.7kW / 100,000 RPM | |

| Number of tool ports | 21ea | |

| Network connection | Wired LAN + Wi-Fi (Mobile Motion App / DOF Sync) | |

| Wet & dry milling | Dry & wet milling | |

| Maximum tilt angle | A-axis ±360° / B-axis ±35° | |

| Operating environment | 15.6-inch display with Motion App 3.0 | |

| All-in-one | All-in-one milling machine including compressor, water pump, and dust collector | |

| Dimensions(W*D*H) |

Machine 545 x 670 x 670mm Table 545 x 670 x 970mm |

|

| Weight | Total 145kg | |

| CAM Software | hyperDENT, Millbox | |

| Power consumption | 220V 16A | |

All-in-One DOF CRAFT 2 Milling Machine is backordered and will ship as soon as it is back in stock.